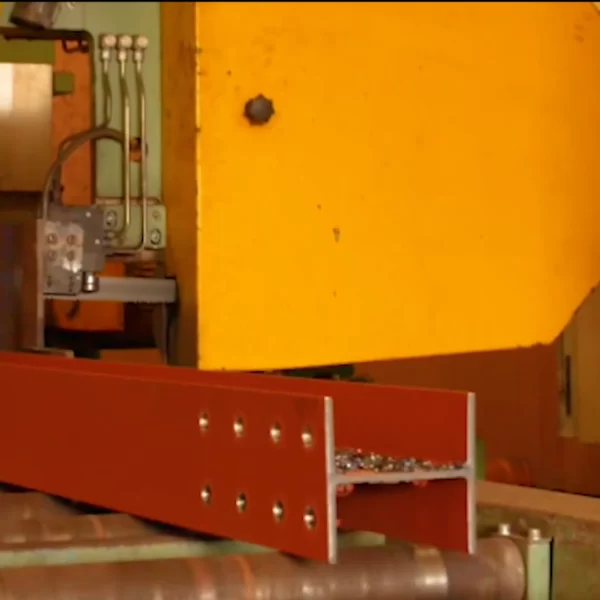

To ensure the optimal performance and longevity of steel, proper surface preparation is crucial. Shot blasting has emerged as a highly effective and popular method for preparing steel surfaces, offering a range of benefits that contribute to improved quality, durability, and cost-effectiveness.

1. Efficient Surface Cleaning:

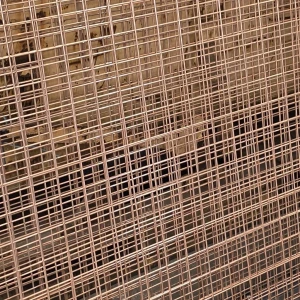

Shot blasting is a mechanical cleaning process that involves propelling small metal or mineral particles at high speeds onto the surface of steel. This action effectively removes rust, scale, contaminants, and old coatings, leaving a clean and pristine surface. Compared to traditional methods like hand tooling or chemical cleaning, shot blasting is faster and more efficient, saving both time and labor costs.

2. Enhanced Coating Adhesion:

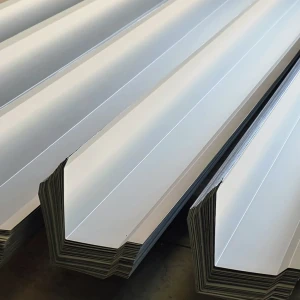

One of the key advantages of shot blasting is its ability to create a profiled surface on the steel. This profile increases the surface area and creates a rough texture, promoting better adhesion of coatings, paints, and finishes. Improved adhesion ensures that protective coatings adhere securely to the steel surface, providing enhanced corrosion resistance and extending the lifespan of the steel components.

3. Cost-Effective Maintenance:

Regular maintenance is essential to prevent corrosion and deterioration of steel structures. Shot blasting offers a cost-effective solution for steel maintenance by efficiently removing corrosion and other contaminants. This process eliminates the need for costly repairs or premature replacements, ultimately saving businesses substantial amounts in maintenance expenses.

4. Environmentally Friendly:

Unlike certain chemical cleaning methods that involve hazardous substances, shot blasting is an environmentally friendly process. The abrasive materials used in shot blasting are often recyclable, minimizing waste and reducing the environmental impact. Additionally, the process generates less dust compared to other surface preparation methods, contributing to a safer and cleaner working environment.

5. Consistent Quality:

Shot blasting provides a uniform and consistent surface finish across large areas of steel. This ensures a high level of quality and uniformity, reducing the likelihood of defects or imperfections in the finished product. Consistent surface preparation is particularly crucial in industries such as automotive manufacturing, aerospace, and construction, where precision and quality control are paramount.

6. Increased Durability:

By effectively removing surface contaminants and creating a profiled surface, shot blasting significantly contributes to the durability of steel components. The process eliminates weak points and ensures that coatings adhere securely, providing robust protection against corrosion, abrasion, and other environmental factors. The result is steel structures and components that maintain their integrity and strength over an extended period.

In the world of steel fabrication and manufacturing, shot blasting has become a cornerstone process for surface preparation. Its numerous benefits, including efficient cleaning, enhanced coating adhesion, cost-effective maintenance, environmental friendliness, consistent quality, and increased durability, make it an indispensable tool for ensuring the longevity and performance of steel structures. As industries continue to seek sustainable and effective solutions, shot blasting stands out as a reliable method that checks all the boxes for optimal steel surface preparation.