Structural Steel Steel Galvanisation

Steel galvanisation stands as a testament to the ingenuity of industrial metallurgy, offering a robust solution to combat the inherent vulnerability of steel to corrosion. This process, dating back to the 19th century, involves coating steel with a layer of zinc to enhance its durability and longevity. As an indispensable technique in modern construction and manufacturing, steel galvanization plays a pivotal role in ensuring the structural integrity and resilience of numerous infrastructure projects worldwide.

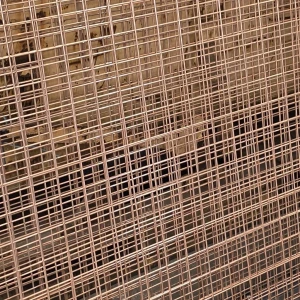

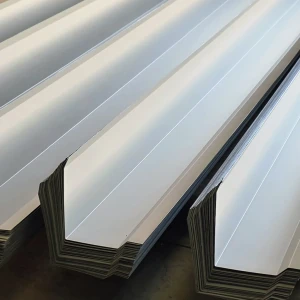

At its core, the process of galvanisation is a marriage of two metals: steel and zinc. Steel, while renowned for its strength and versatility, is susceptible to corrosion when exposed to moisture and atmospheric elements. Zinc, on the other hand, boasts remarkable corrosion resistance properties. By applying a protective zinc coating onto the surface of steel, galvanization provides a formidable barrier against rust and corrosion, extending the lifespan of steel structures manifold.

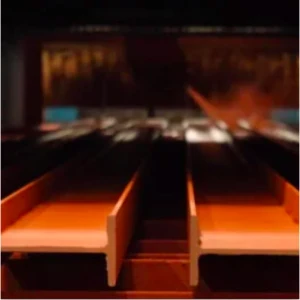

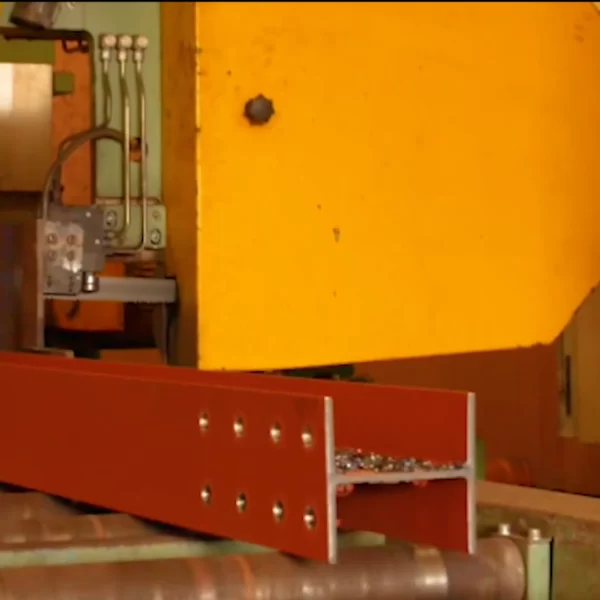

The galvanisation process typically involves three main steps: surface preparation, hot-dip galvanizing, and post-treatment. Surface preparation is crucial to ensure the adhesion and uniformity of the zinc coating. It involves thorough cleaning of the steel surface to remove any contaminants, such as dirt, oil, and rust, through processes like chemical cleaning or abrasive blasting. Once the surface is properly cleaned, the steel is immersed in a bath of molten zinc in the hot-dip galvanising stage. This immersion allows the zinc to bond metallurgically with the steel, forming a series of zinc-iron alloy layers on the surface. Finally, post-treatment processes may be employed to further enhance the coating's aesthetics or performance, such as chromating or painting.

The benefits of steel galvanisation are manifold and far-reaching. Foremost among these is its unparalleled corrosion resistance. The zinc coating acts as a sacrificial anode, corroding preferentially to protect the underlying steel substrate. This sacrificial protection mechanism ensures that even if the coating is scratched or damaged, the steel beneath remains shielded from corrosion. Consequently, galvanised steel finds extensive applications in outdoor environments, such as bridges, highways, and utility poles, where exposure to moisture and harsh weather conditions is inevitable.

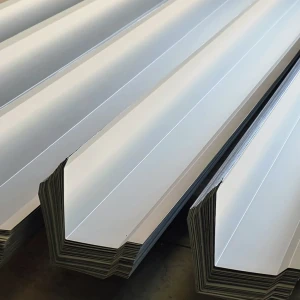

Moreover, galvanised steel offers exceptional durability and low maintenance requirements. Unlike organic coatings, such as paint, which require periodic reapplication, galvanised coatings can last for decades without significant deterioration. This longevity translates into substantial cost savings over the lifecycle of a structure, as maintenance and replacement expenses are minimized. Additionally, galvanised steel is highly resistant to mechanical damage, abrasion, and UV radiation, further bolstering its suitability for long-term outdoor exposure.

Furthermore, steel galvanization is an environmentally sustainable choice compared to alternative corrosion protection methods. Zinc, the primary component of galvanized coatings, is abundantly available and fully recyclable. In fact, galvanized steel is one of the most recycled materials globally, with recycling rates exceeding 90%. By extending the lifespan of steel products and reducing the need for frequent replacements, galvanization contributes to resource conservation and waste reduction, aligning with the principles of sustainable development.

In conclusion, steel galvanization epitomizes the fusion of innovation and practicality in the field of metallurgy. Through its ability to fortify steel against corrosion and prolong its service life, galvanization has become indispensable in diverse industries, from construction and infrastructure to automotive and manufacturing. As society continues to confront the challenges of sustainability and resilience, the enduring legacy of steel galvanization shines as a beacon of progress, offering a blueprint for safeguarding our built environment for generations to come