Steel Types & Applications

Undoubtedly over the last century, steel has played a pivotal role in Ireland’s construction, manufacturing and industrial sectors and that it will continue to be integral to our progress and development going forward too.

Our steel guide aims to help everyone understand the types of steel available, their application, and the role steel plays in our modern world.

What is Steel

Steel is an alloy primarily consisting of iron mixed with a small percentage of carbon. However, contemporary steel is far more complex and intricate than that. The amount of carbon used coupled with the alloys added to the steel and the processing methods employed gives us literally thousands of different grades of steel.

This makes steel an extraordinarily versatile and useful material suitable for a wide range of applications.

Types of Steel

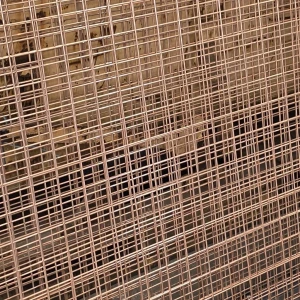

The array of steel types available today is endless, from the galvanised steel’s armour against corrosion to the flexibility of steel mesh and everything in between. The possibilities are huge!

However, the different compositions and treatments divide steel into four main steel types: carbon steel, alloy steel, stainless steel and tool steel. These are then also classified or graded based on what they contain and their different properties.

In this guide, we also include some of the most commonly used types of steel used in construction: galvanised steel and structural steel.

Carbon Steel

Constituting approximately 90% of steel production, carbon steels are generally very strong and have a high level of wear resistance.

Carbon steels contain only trace amounts of other materials and can be classified as mild/low, medium and high carbon steel.

Mild/low carbon steels refer to carbon steel made of up to 0.3% carbon which is perfect for applications where tensile strength isn’t needed. Mild carbon steels are malleable and easily formed and can be used to make machinery, automotive bodies, pipes, wires, medical equipment, bolts and other structural components.

Medium carbon steels contain between 0.3% and 0.6% carbon and up to 1.6% magnesium. Although more difficult to weld or form, medium carbon steels have improved strength compared to low carbon steels, making them usable for railway tracks and a wide variety of machinery parts.

High carbon steels contain more than 0.6% carbon, up to 1.5% and up to 0.9% magnesium. High carbon steels are primarily used in machine parts that require hardness and wear resistance, such as springs and high-strength wires.

Alloy Steel

Alloy steels combine carbon steel with various alloying elements such as nickel, copper, aluminium, cobalt, tungsten or vanadium to enhance specific characteristics. Combining carbon steel with these elements improves its strength, ductility, machinability and corrosion resistance.

Alloy steels are essential in aerospace, automotive manufacturing and oil and gas industries, where demanding conditions require robust materials.

Stainless Steel

Containing a minimum of 10.5% chromium content, stainless steel has high corrosion resistance making it indispensable in environments where rust and deterioration are concerns. While some stainless steel grades are suited for construction, they are most commonly used to make knives, cookware, food processing machinery, pipes, electrical devices and medical equipment.

Tool Steel

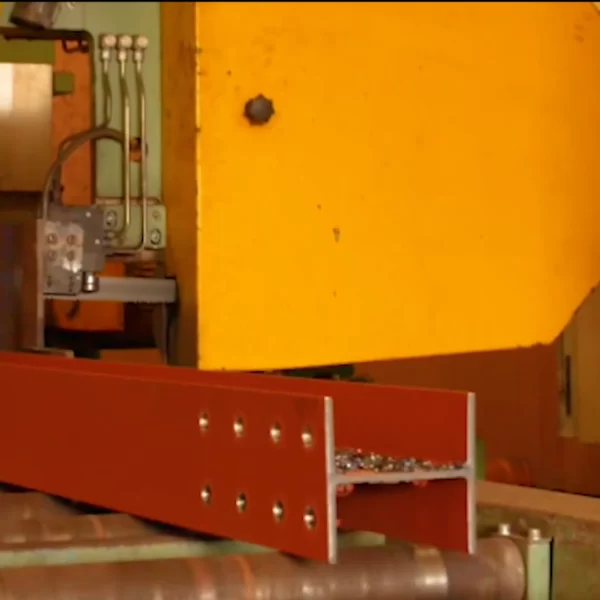

Tooling steels, as the name suggests, are primarily used for tooling activities such as drilling or cutting. Tool steels are a subset of alloy steel that contain tungsten, molybdenum, cobalt and vanadium, which make them incredibly durable and heat resistant.

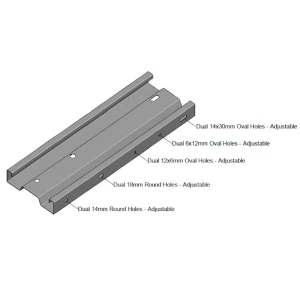

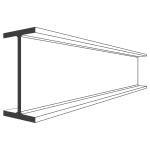

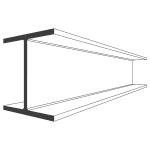

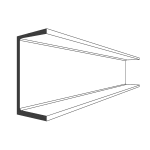

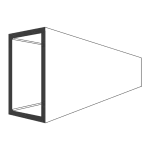

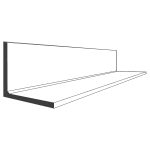

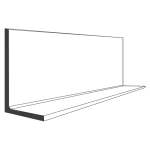

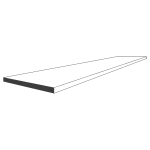

Structural Steel

Ever looked at a bridge or skyscraper and wondered how it was built? When it comes to large-scale infrastructure, structural steel takes centre stage. With excellent strength-to-weight ratios, structural steel allows us to build structures that can support heavy loads while remaining structurally sound.

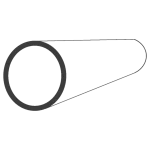

The most common structural steel used includes flats, rounds/squares, angles, rebar steel, steel mesh, channels, IPE beams, plates and sheets, hollow sections, universal beams and universal columns.

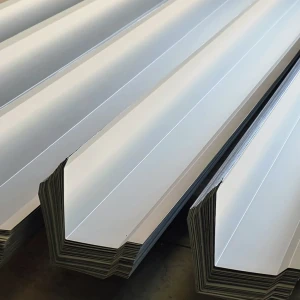

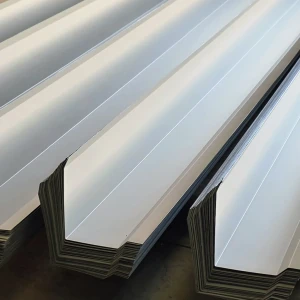

Galvanised Steel

Galvanised steel is carbon steel that’s been coated with a layer of zinc through galvanisation. This protective layer protects it against corrosion and moisture, increasing its lifespan.

Galvanised steel is commonly used in outdoor structures such as fences, roofing and guardrails. At Hibernia steel we supply only the highest quality steel and the same is said for our galvanised tubes and pipes – you can find out more about our range of galvanised steel here.

Peace of mind

Your project deserves the very best, and at Hibernia Steel we are ready to deliver just that! Contact us now at +353 41 9831702 and let your visions come to life in steel-framed style.